Weighwell Engineering Ltd specialises in advanced portable train weighing systems that are designed to meet the specific requirements of rail maintenance depots and freight terminals. The company’s systems are suitable for both the static and in-motion weighing of rail vehicles and deliver accuracy, flexibility, and ease of use across a range of environments.

Portable train weighing systems

Weighwell’s award-winning Portable Train Weigher (PTW) has redefined train weighing within the rail industry. With its innovative, patented design, the rail scale can be installed quickly and without the need for permanent track modifications. such as cutting, drilling, or welding.

With a compact size, measuring only 500mm (or 556mm for the heavy-duty models), the PTW fits between rail fastenings, making it easy to install into existing infrastructure. Engineered for adaptability, the PTW works with a wide range of track gauges and rail profiles.

The Weighwell PTW is the ideal solution for weighing all types of rolling stock, including trams, metros, locomotives, freight wagons, passenger railcars, or high-speed trains.

Flexible static or in-motion rolling stock weighing

The PTW is suitable for both static and in-motion weighing, with dedicated interfaces tailored to many applications, such as routine maintenance assessments in railcar facilities or one-off freight train inspections. Weighwell’s portable weighing system ensures accurate, real-time measurements that can improve operational efficiency.

Static train weighing systems for rail depots

When trains are weighed statically, any imbalance or uneven weight distribution can be detected early, preventing safety issues and reducing maintenance costs.

The company’s Static Train Weighing Systems provide precise individual wheel weight measurements, making them essential during the manufacturing, maintenance, and overhaul of rolling stock. These systems are available in a variety of configurations to suit a range of operations.

Accurate rolling stock axle weighing

The Axle Weighing System, featuring a single PTW unit, statically weighs each individual axle of the rail vehicle and provides immediate feedback on any imbalances across the wheelset. This instant weighing data enables operators to make necessary adjustments and maintain precision during the maintenance process.

Enhanced train weighing precision with multiple PTW units

For maximum precision, Weighwell recommends using multiple PTW units to weigh each bogie or railcar simultaneously. This setup is ideal for maintaining safety, reducing vehicle movements, and optimising depot maintenance practices across entire rail fleets.

In-motion railway weighing systems for rail freight

Weighwell’s portable in-motion train weighing system is designed to meet the demanding needs of freight operations, weighing trains at speeds of up to 5kph. It delivers accurate check-weighing results and is suitable for use in industries such as aggregate handling sites, quarries, and metal recycling facilities, helping operators monitor loading in real time.

By identifying overloading or eccentric loading, the in-motion rail scale improves safety, reduces the risk of derailment, and ensures compliance with weight limits. Installation takes just 15 minutes and battery-powered system is operated via a simple, user-friendly interface. This makes it a versatile and reliable solution for any dynamic weighing requirements.

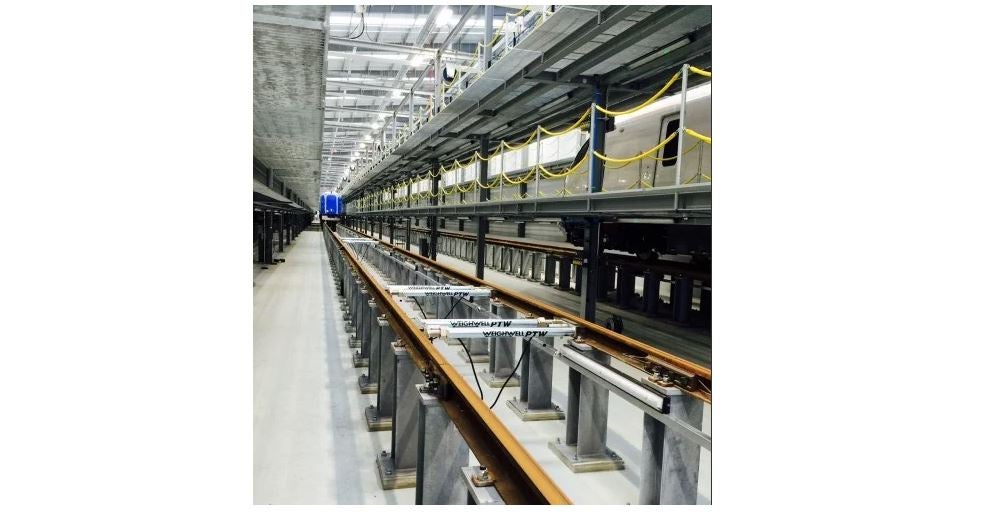

TrackCell™ bogie workshop fixed weighing system

The company’s TrackCell™ Bogie Workshop System is a fixed weighing system that can integrate seamlessly with both new and existing bogie test machines. Suitable for the manufacturing and refurbishment of bogies, this system can also be used for weighing railcars and locomotives.

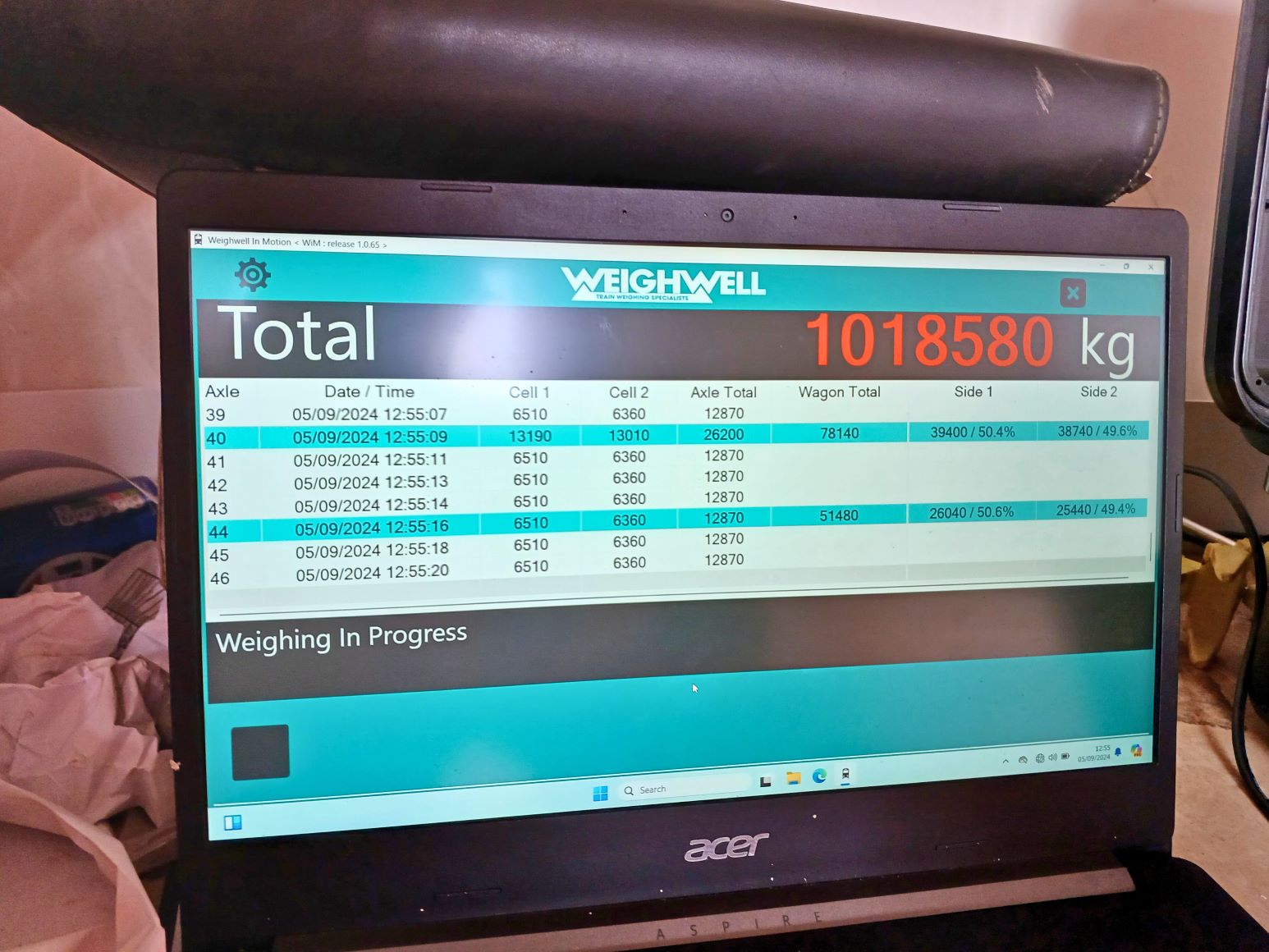

Software and indicators for weighing trains

To complement its weighing systems, Weighwell provides software and indicator interfaces for real-time analysis. Operators can view and record weighing data easily, enabling rail operators to make informed decisions.

Weighwell’s software features a graphical interface and detailed reporting and can be accessed using a laptop or computer. The company’s digital indicators are housed in a rugged carry case to protect them from the environment and help them to last longer.

Train weighing system hire

Through its hiring service, Weighwell offers both short-term and long-term rental options for static and in-motion PTW systems. The company will deliver and install the system and also provide operator training. This provides clients with a fast and flexible way to meet any temporary or project-specific weighing requirements, without compromising accuracy or safety.

About Weighwell Engineering Ltd

Established over 35 years ago, Weighwell has built a strong reputation within the rail industry for high-quality, reliable products that are supported by exceptional customer service. The company has installed weighing systems in over 40 countries and has developed long-term partnerships with some of the most recognised names in the rail sector, including Hitachi, Siemens, DB Cargo, and Cemex. Weighwell has experience across multiple areas of the rail industry, enabling it to provide solutions that meet a wide variety of operational requirements.

From in-motion to static weighing systems, Weighwell offers proven solutions designed to meet the specific needs of many different rail operation. To learn more about the company’s portable train weighing systems, visit the product pages, or get in touch using the contact form above.