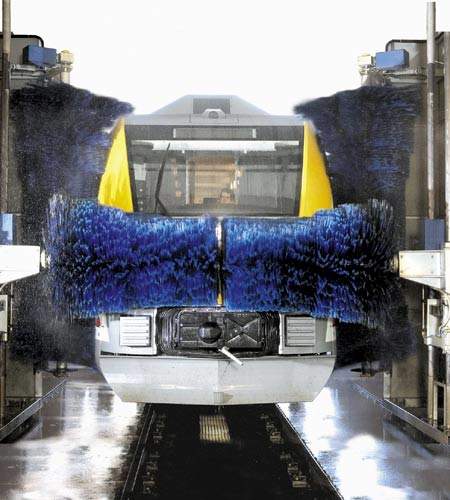

Westmatic is a specialist in train and heavy-vehicle washing systems. Washing trains can be very complicated but with the Westmatic Twin Line it is easy. These highly technological machines sense the shape of the different rail cars and wash in both directions.

The Twin Line’s high-density brushes are profiled to match the train’s contour and can wash the front, roof and rear in a single wash cycle. To optimize results the wash system can be delivered with dryers / blowers and window squeegees.

Electric and diesel train washing equipment

Westmatic’s train wash equipment is available for both electric and diesel trains and has minimal installation dimension requirements. Optional equipment includes:

- Heating / cooling arches – oxalic acid / detergent arches, detergent pumps, detergent metering systems

- High pressure arches and pumps – chassis wash / side-spray with high pressure

- Dryer / blowers with window squeegees – manual spray equipment

- Water recycling system with ozone generator – Renaren water purification system

Train washer water-treatment system

Environmental thinking does not have to be difficult – this is proven by Westmatic’s brilliant water treatment system. The water from the train washer is purified in two stages – water recycling and water purification.

Westmatic’s water treatment system entirely fulfils even the strictest of regulations regarding water quality standards. This includes the rules of the Swedish National Environmental Protection Agency, which are among the most stringent in the world. All parts can be delivered separately.

Rail washer water-reclamation system

Water recycling and re-use is environmentally and fiscally beneficial and therefore an increasingly important component of any modern vehicle-wash system. Westmatics’ proven water reclamation system utilizes cyclonic separation to achieve water quality of 10μm.

Odor control is achieved by use of ozone injection, which safely and effectively eliminates any odor-causing bacteria in the system as well as accelerating solids precipitation. This process enables water reclamation of up to 85%, greatly reducing sewer impact fees as well as monthly bills.

For decades, Westmatic has been producing effective, cost-efficient water reclaim equipment that meets the stringent requirements of the Swedish National Environmental Protection Agency and complies with ISO 14001 standards.

Water purification system

In applications where waste wash water must be purified, Westmatic’s Renaren system is the answer. Water that is not recycled passes through the oil / water separator and into Renaren. The method is based on electro-flocculation, which is a technical combination of electro-flotation and electro-precipitation. No chemical supplements are needed during the purification process.

Renaren is so effective that it can produce a water purification level of more than 99%. After having gone through the Renaren, the water can then proceed out into the sewage system.

Renaren has proved to be useful in many lines of business where purification of oil-mixed water is necessary. It is patent-protected and has been DNV-certified for ship installations.

Vehicle washer card-reader system

Any model of Westmatic’s automated and manual vehicle wash equipment can be coupled with the Wash Control 3000 card reader system to create a highly profitable and dependable retail wash bay.

The vehicle can enter the bay after the driver swipes a proprietary ‘wash’ card. At the Wash Control 3000 console the driver selects from a menu of both manual or automated wash programs, then all of the selections are billed. Once the automated wash program is complete, the exit door opens and the vehicle departs. The bay is now ready for the next wash.

The entire process is extremely user-friendly, eliminating the need for personnel to operate the wash equipment. Wash Control 3000 makes the washer accessible day and night, without the need for permanent staffing.

Train identification and registration systems

Westmatic also supplies systems for identification and registration of trains.