Delivering intelligent technologies to offer protection from dangerous environments in a safe and efficient manner.

Zonegreen’s team of experts has developed an impressive range of intelligent technologies to offer safety-related products and innovative planning of train maintenance operations, and has forged an unrivalled reputation for quality, safety and reliability.

Depot personnel protection systems, interlocking solutions, as well as railway maintenance planning applications and out-of-gauge warning systems are installed worldwide and can be used in sectors as diverse as transport, petrochemicals and aerospace.

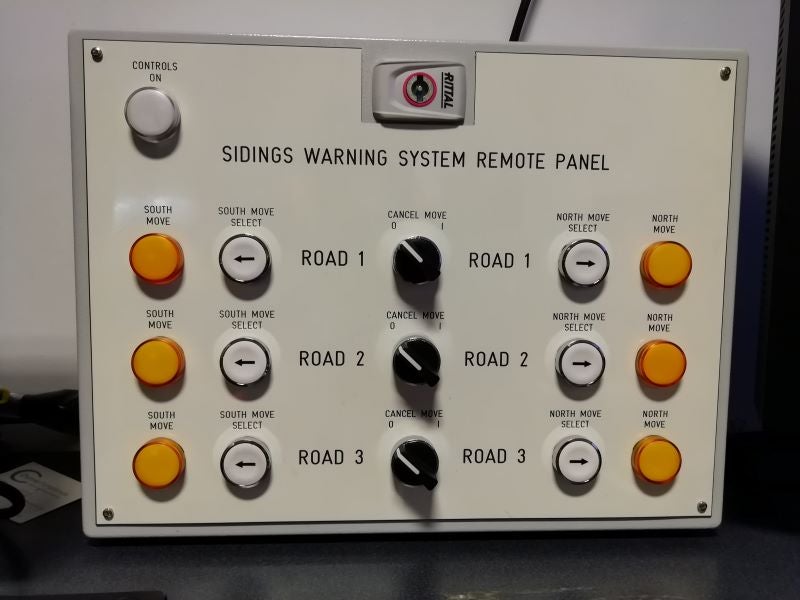

Depot personnel protection system

The Depot Personnel Protection System, commonly referred to as the Depot Protection System, is specialised and designed to ensure the safe and controlled movement of rail vehicles into and out of depots, so that maintenance operations can be conducted without endangering staff or the depot infrastructure.

Zonegreen’s SMART DPPS™ is highly advanced, state-of-the-art and incorporates intelligent, distributed communication technology, as well as electronic personnel datakeys to uniquely identify staff working in different safety zones.

The Zonegreen’s SMART DPPS™ allows the user to:

- Login from any convenient point of access using a unique personnel datakey, replacing the need for padlocks

- Easily identify personnel who are logged onto different roads

- Interlock with other third-party equipment/systems to prevent unsafe movement

- Protect working staff and other interlocked equipment from vehicle movement

- Capture personnel logon/logout and movement history for future audit purposes

Additionally, where overview software is included, the status of Zonegreen’s SMART DPPS™ and personnel logged on will be visualised graphically from the depot manager’s office via a wall display.

Points converter for powering manual points

Designed to increase railway depot and workshop safety and efficiency, the Zonegreen Convertor allows the automation and remote operation of manual / hand points switches and rail road crossings.

Benefits of powering your manual points

- Enhanced safety by reducing the potential for slips, trips and falls

- Increased depot efficiency and speeding up of operations by eliminating many stops and starts

- Expandable: routes can be pre-set, re-configured and upgraded at any time

- Traceability includes an event logging system that allows the depot manager to keep a record of the points operation

- Low cost

- LUL approved

The Zonegreen convertor system comprises two parts:

- Point Machine Conversion System: a point machine conversion device is attached to an existing manually-operated switch without compromising the integrity of the existing mechanism. It does not require any civil works or changes in the operating procedures to be installed. Each converter can be used as a stand alone or multiple units can be installed operating together with routing

- Radio Remote Operator’s Controller: an intuitive handset that allows the operator to remotely control the points system. It can be either hand portable or cab mounted. A centralised control system is also available via windows PC interface that offers route planning and visualisation. The radio controller can also be used in a route selection mode, whereby one command can operate several points and crossings simultaneously

Train maintenance planner

The planning of train maintenance operations is still commonly conducted on a big whiteboard located in the operations control room, on which the train units that require servicing, maintenance tasks, arrival and departure times are listed. These are updated manually either in a tabular form or on top of a graphical layout representing a bird’s eye view of the depot.

Zonegreen’s depot manager, as a multi-user, web-based graphical task planning application, is a cost-effective replacement of the whiteboard. It consists of two main views: a graphical layout representing the depot on which users can position trains and create and assign maintenance tasks, and a tabular layout to plan trains’ scheduled arrivals and departures.

The train maintenance function of the depot manager allows staff to:

- Plan train-unit maintenance activities

- Easily visualise train locations in graphical layout

- Accurately update and synchronise maintenance information

- Share and disseminate maintenance information to different locations in a convenient way

- Capture maintenance activities and generate reports, reducing the manual tasks of filling in maintenance forms and paperwork

Safety interlocking systems

The concept of interlocking has been applied to create increasingly sophisticated systems with the potential to prevent personal injury or costly damage. These systems can stop unauthorised train movements or actions by personnel not following stipulated safety procedures.

A typical installation is vastly superior to a permit to work system (which depends on personnel obeying written rules); physically prevents access to high-level working platforms while overhead line equipment remains live; isolates power to overhead crane while OLE is live; and ensures a safe system of work.

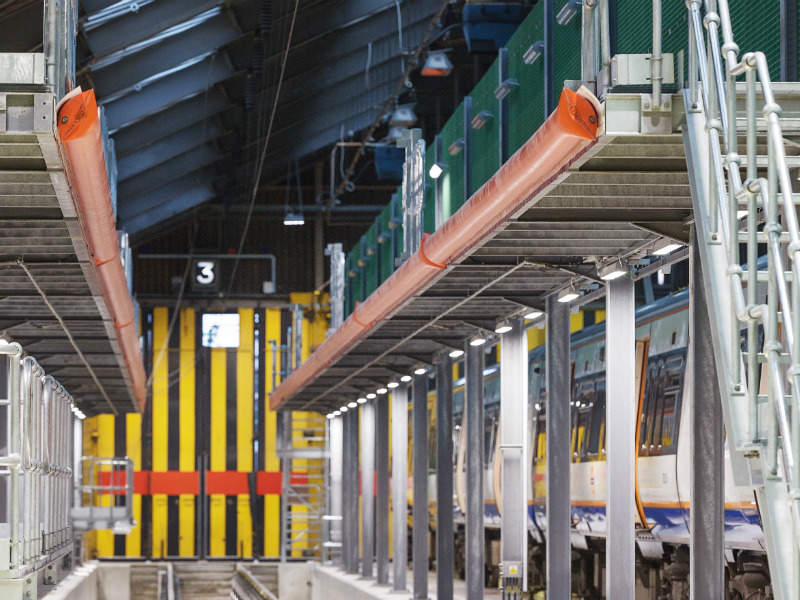

Out-of-gauge warning system

Zonegreen’s out-of-gauge warning system has been developed in response to rail industry demand for a ‘gold standard’ in obstacle detection systems. It is based around a series of non-contact laser rangefinder sensors and prevents a train from leaving the depot if its side skirt has not been fully closed.

If the sensor detects any kind of obstruction, for example an open side skirt, it will trigger an alert on the outbound visual warning board and illuminate a driver warning stop board on the depot exit road. The stop signs will remain illuminated until the warning is reset via the master keyswitch.

The out-of-gauge warning system is flexible and has a range of programmable options, such as a delayed response to help prevent the triggering of false alerts. It may also be expanded to cover the entire side area of the vehicle using a multiple sensor arrangement.

Depot safety-related equipment

Zonegreen offers a range of safety-related equipment for depots, including but not limited to:

- Ground position signals

- High level or pit warning beacons – static or flashing

- Klaxons

- Speed indication detectors

- Stop and proceed boards

- Electronic wheel-detect switches (treadle switch)

- Portable warning systems

Maintenance and installation works at rail and tram facilities

Zonegreen is now able to undertake additional servicing maintenance and installation works at rail and tram maintenance facilities (IRSE installers) in addition to its normal servicing of depot personnel protection and interlocking systems. Zonegreen now offers the following:

- Points / switches

- Track circuit renewal (IRSE licensed)

- Signal including axle counters

- Cable testing (SMTH standards)

- Barrier systems

- AWS & TPWS systems