The system GAAS80 is used in fixed welding plants for joining short rails to long welded rails. It forms the core item in the welding plant.

The system GAA100 is used for welding of turnout components such as welding of rails to frogs or for switchblades. Schlatter machines are very rigid in design and are well known for their high productivity, reliability and long life. Many machines from the first series, commissioned roughly 30 years ago, are still in daily use.

System GAAS80

The GAAS80 welds short rails of any length to long welded rails up to 500 m lengths and even longer. Its main feature is the exact lateral alignment of the running edge and vertical alignment of the running surface. The web clamping device is independent from the electrodes and it ensures the rails do not slip during upsetting. Directly after completion of the welding process the integrated deburring device removes the burr.

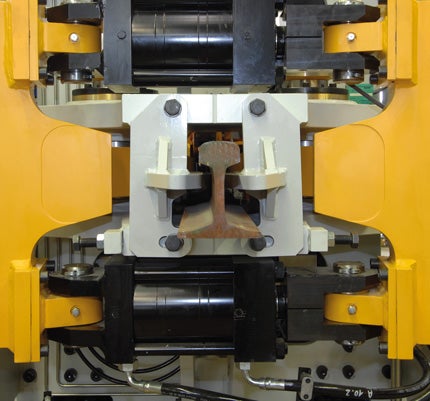

System GAA100

The GAA100 is used for welding components in turnout manufacturing plants. The wide welding range allows high quality welding of nearly all types of components used for turnouts. The four clamping units with 1000 kN force each ensure that the parts do not slip during upsetting. Worldwide the GAA100 successfully welds high resistant manganese frogs with rails with the intermediate stainless steel insert.